loper

Platform Soles Kit White Platform Soles Kit

Platform Soles Kit White Platform Soles Kit

Couldn't load pickup availability

What's inside?

High Soles kit / White

- Outsole

- insole

- Instructions paper

- Pattern

- rope

- thread

- It has a needle.

MATERIALS

Please bring your own leather and shoelaces of choice.

(For first-time buyers, we recommend genuine leather or synthetic leather. For genuine leather, a softer type with a thickness of 2mm or more is preferable, and for synthetic leather, thicker materials are preferable. Thinner materials are less durable and may not keep their shape as well.)

If you would like to purchase materials, please order here .

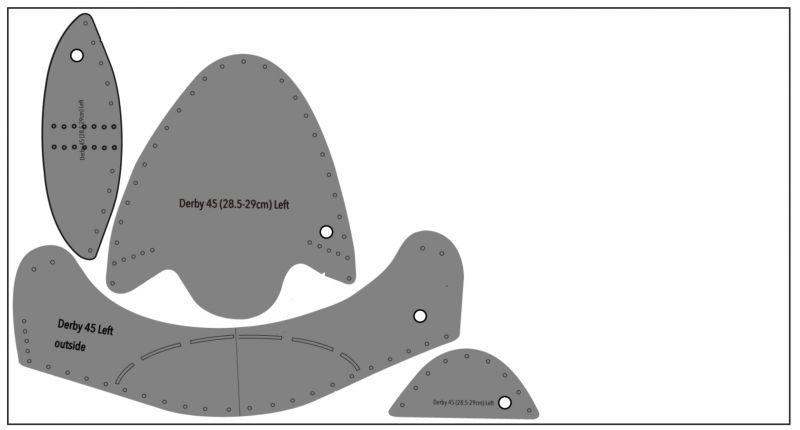

PATTERNS

The High Soles Kit comes with a pattern for Derby shoes (lace-up shoes).

If you would like to make shoes with a different design, please place a separate order here (we have free and paid patterns available).

SIZE

Sizes vary slightly depending on the brand and model, so please refer to the table below and choose the size that matches your usual shoe size.

Color of Soles

Rope and Thread

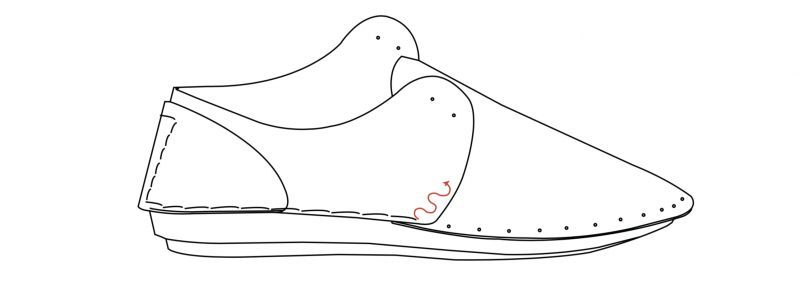

How to make Derby shoes

Cut along the lines with a cutter or scissors.

Step 4

Punch holes in the cut out pattern.

Step 5

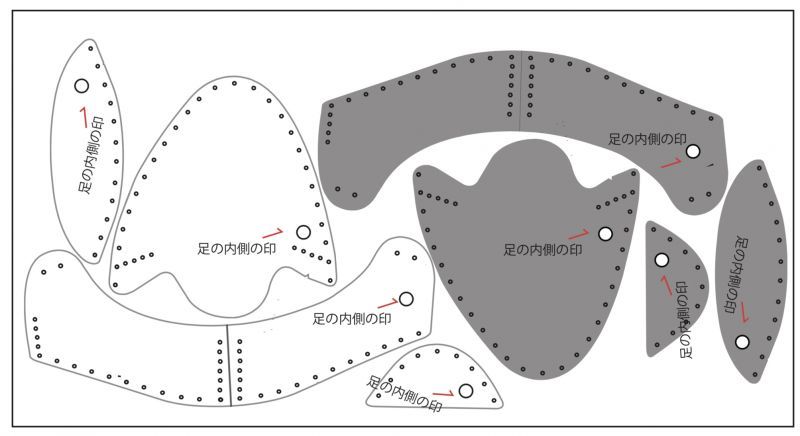

Follow the pattern and mark the back of the material you are using with a pen.

Step 6

After drawing all the shoes on the left side, turn it over and draw the shoes on the right side.

The shoe patterns are available in left and right.

Mark the inside of the foot on the pattern, and be careful not to mix up the right and left patterns!

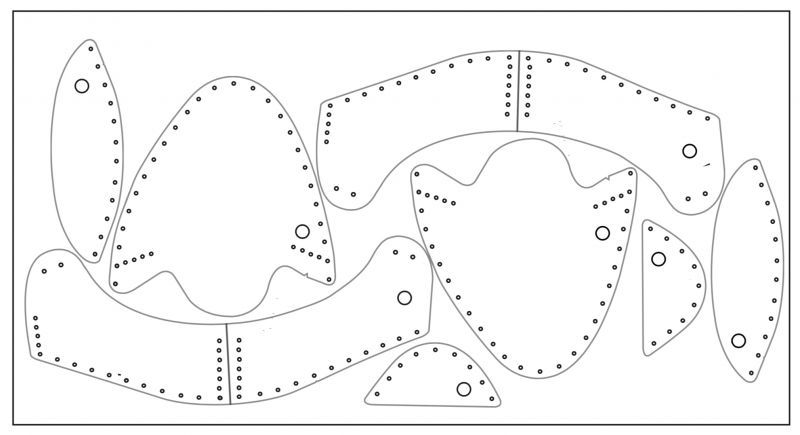

Step 7

Cut along the lines and marks with a knife or sharp scissors to make holes.

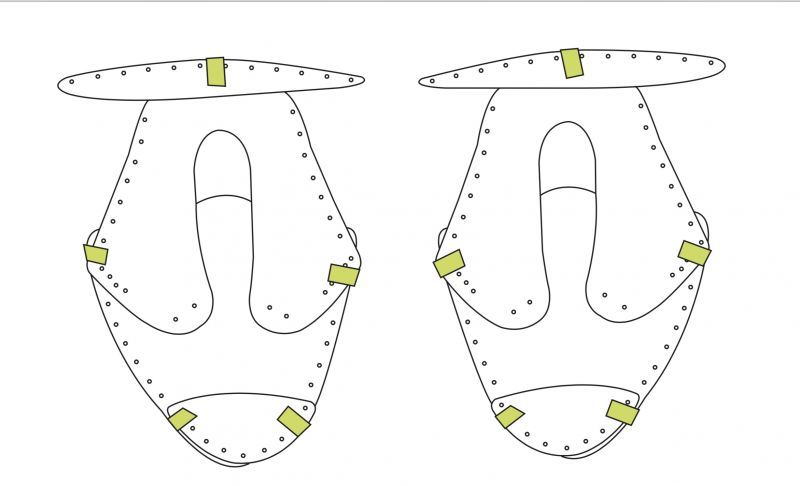

Step 8

Once all the patterns have been cut, temporarily secure each left and right part in the correct position with masking tape.

Step 9

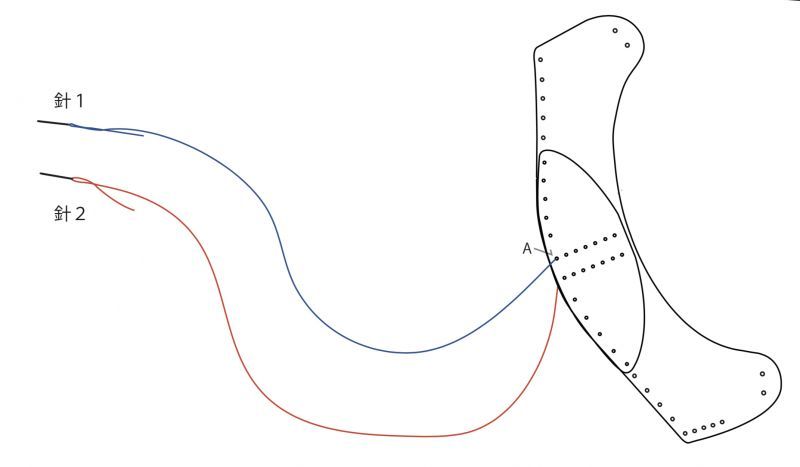

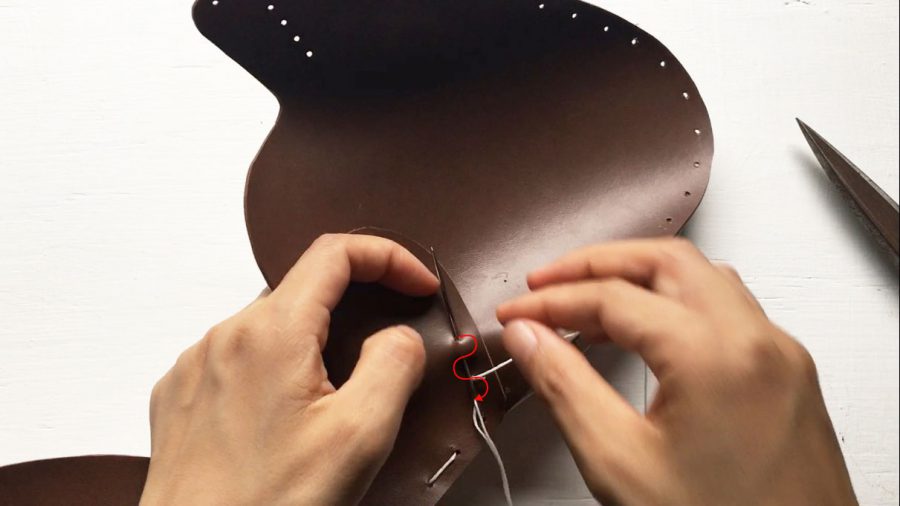

Thread a needle through each end of the included thread.

Insert the needle at position A and thread it through until both threads are the same length.

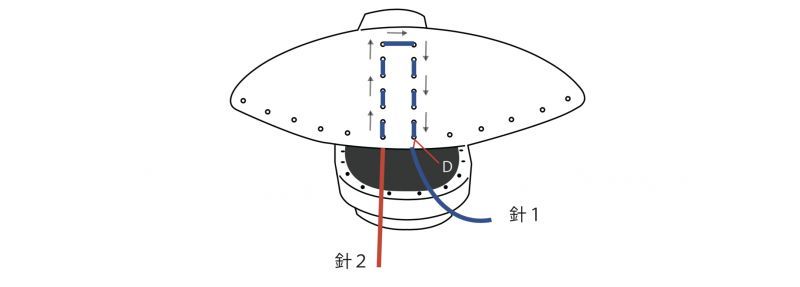

Use needle 1 to sew up to point D.

After sewing needle 2 up to point D, insert needle 1 into the sole at position D.

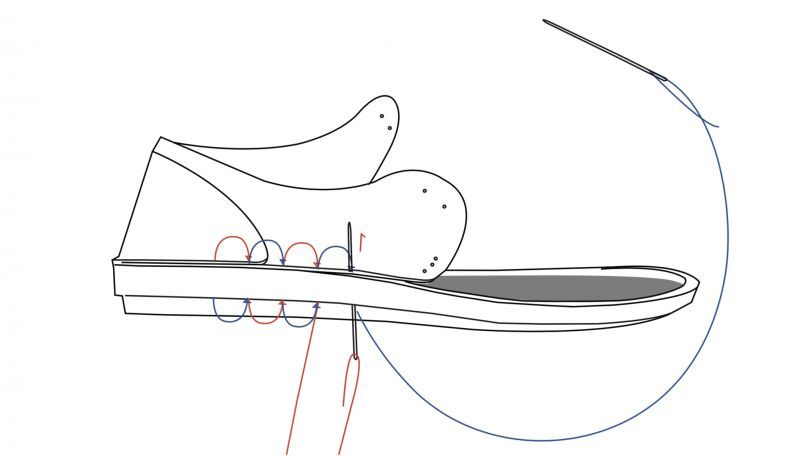

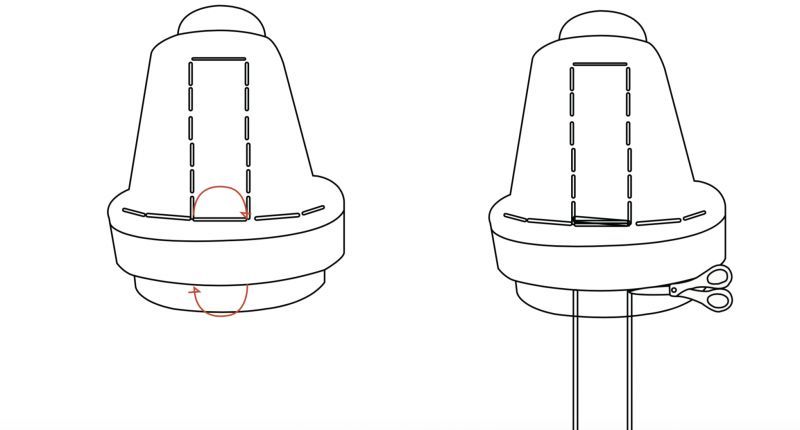

Step 10

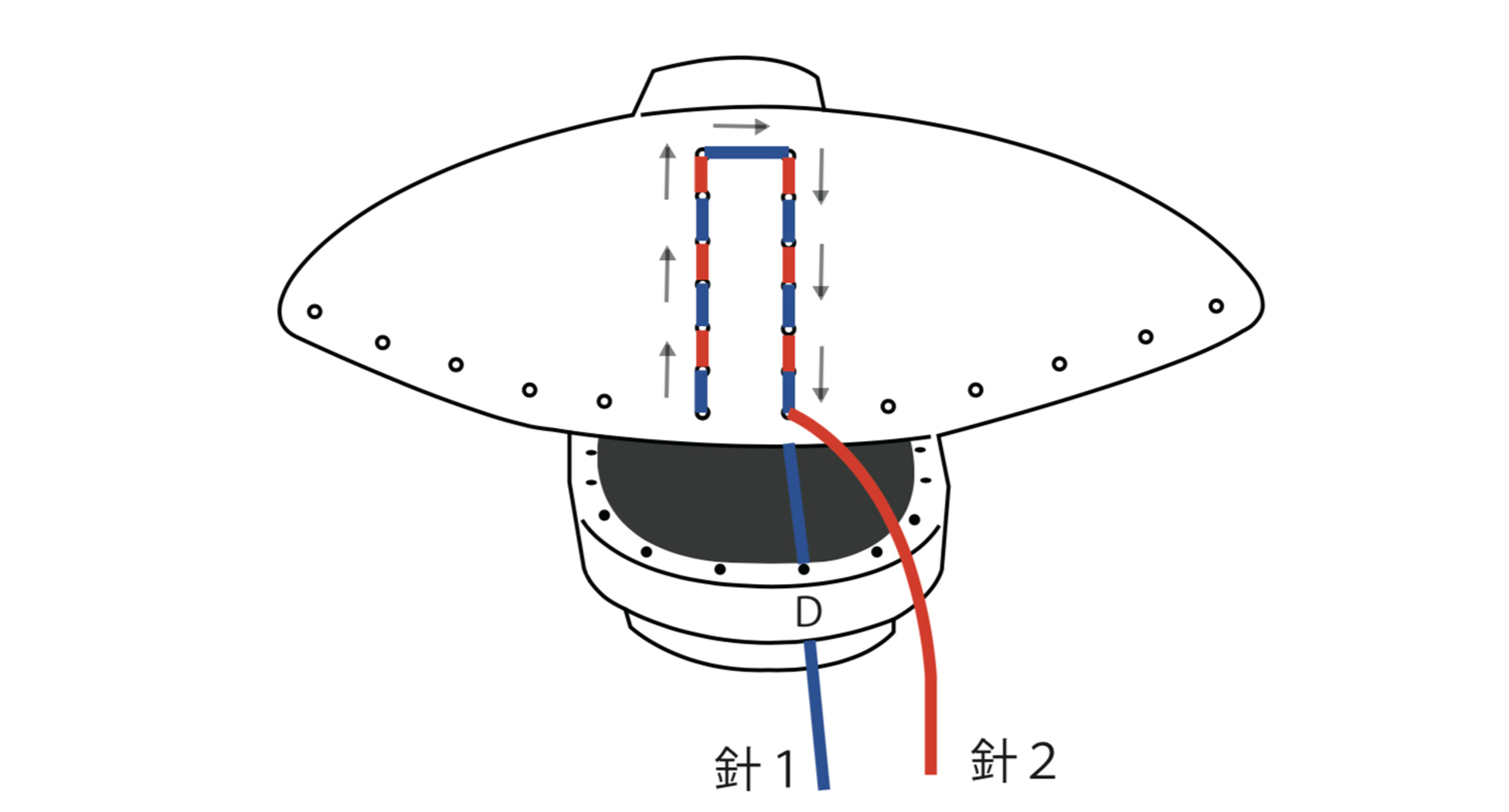

Now it's time to sew the upper and sole together. This is done using a saddle stitch, where the needles on both ends are sewn together alternately.

The side stitching is done with one stitch and then comes back in the same way from the edge.

To finish off the final stitch, double stitch both threads and trim them at the ends.

Put the insole in, thread the laces and you're done!

This time I used brown synthetic leather, but just changing the material can really change the feel. It's also fun to create your own original design based on a pattern.

Soles recognized by shoe designers (craftsmen)

We also asked Mr. Iida, a designer/shoemaker at DECO&BOCO, to purchase the soles and create a sample.

It has been well received by artisans who normally spend a lot of time and effort on their work. Because it can be made in a relatively short amount of time, they plan to create a second line using "LOPER" separate from their regular line.

It's also a great place for a shoemaking workshop.

Customer testimonials

LOPER spreads DIY awareness

My goal is to one day make a kids' size "LOPER" so that all children can have the experience of making their own shoes.

There are many deep-rooted problems hidden in the world of shoemaking.

Making something so difficult yourself makes it fun.

When you live using things you have made yourself, or wear things that you know who made them, you will develop a strong attachment to them.

Such a life would be richer and more enjoyable than one that is constantly accumulating and wearing itself out.

I want to make my own shoes! I want to make them and give them as gifts! I want to start a shoe brand! If you're one of those people, I definitely recommend giving it a try.

You can download the pattern from this link .

share