loper

Design and Create @Osaka

Design and Create @Osaka

Couldn't load pickup availability

Travel time :

Participation fee and conditions : (Includes all materials and necessary items such as soles, insoles, thread, tools, etc.)

Low-cut shoes 15,400 yen (tax included)

option

High-top shoes and loafers: 2,200 yen (tax included)

Tassel 3,300 yen (tax included)

Fur 4,950 yen (tax included)

Prices will vary depending on other options.

Payment : Please make a prepayment of the basic fee of 15,400 yen (tax included ) at the online shop.

If you would like to add options or make them high-cut, you can purchase additional items at the workshop venue by cash or credit card.

Please choose the material from the ones we have available.

You can also bring in your own materials and have them used for shoe parts!

Capacity : 4 people

Location : Maniac Nagaya, Gamo 4-chome, Osaka (search for it on Google)

Maniac Row House, 4-4-18 Gamo, Joto Ward, Osaka City

Size: 8 sizes from 22 to 28.5 cm

design

You can choose from the above six types after trying on samples on the day.

You can see examples of shoes you can make here .

We only offer the production of loafers and high-top shoes to customers who have attended our workshop for the second time or more.

We would appreciate your understanding.

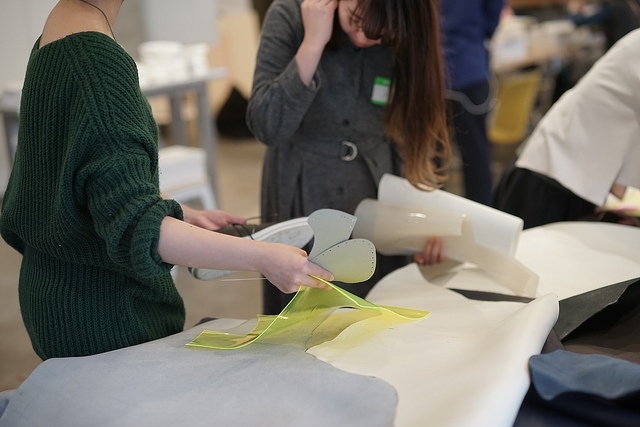

Making shoes is fun.

LOPER is a system that allows you to make shoes without using adhesives.

Although it varies from person to person, it takes about 3-5 hours to complete one pair of shoes.

Everyone's feet are different.

In mass-produced shoe manufacturing, shoes are made based on an average foot last, so it is actually difficult to find shoes that fit your feet perfectly.

LOPER allows you to easily adjust the pattern to fit your foot when making the shoe upper, making it possible to create shoes that are more tailored to each individual's foot.

If you know how it works, you can repair it.

If you make your own shoes, you can repair them yourself when the soles wear out or if you want to customize the design.

Even if you are a first timer, please feel free to join us.

Choice of materials

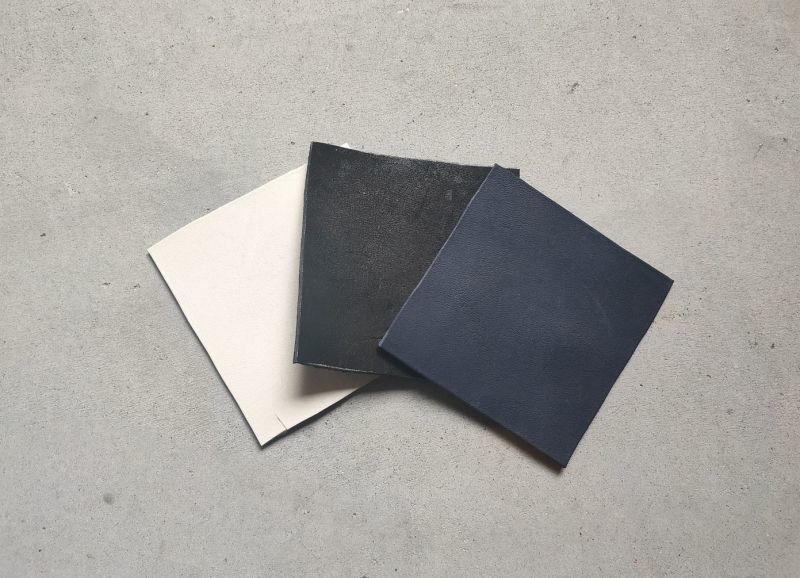

Glove leather in white, black, and navy

Glove leather in white, black, and navy

This material was developed as leather for making baseball gloves .

The raw hide is made from the finest North American steer. It is glove- tanned to preserve the fibers, resulting in a lighter, less wrinkle-prone leather than traditional glove leather , with the leather's inherent flexibility and soft texture making it perfect for shoemaking.

Tochigi Leather Nume/Camel

Tochigi Leather Nume/Camel

Tochigi Leather specializes in the production of cowhide leather (vegetable tanned leather), and this is the best leather in Japan, finished with almost no surface processing.

It is flexible and durable, and as the years go by,

The way it changes and develops into a richer flavor is appreciated not only in Japan but around the world.

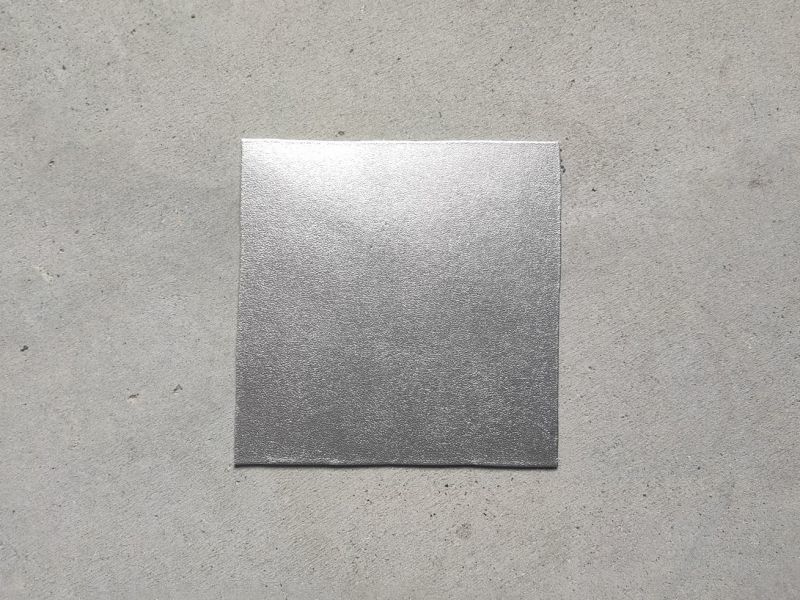

Super Metallic [Lead and Phthalate Free] Silver

The soft and gentle texture of metallic leather, with its pearlescent shine and soft pastel colors, gives your products an elegant finish.

Microfiber

This microfiber suede is the result of Asahi Kasei's unique technology. Its unique three-layer structure is made from ultra-fine short fibers and water-based polyurethane. It is made from environmentally friendly materials.

All you need to do to care for it is brush it.

This material is used for the interiors of luxury cars and sofas.

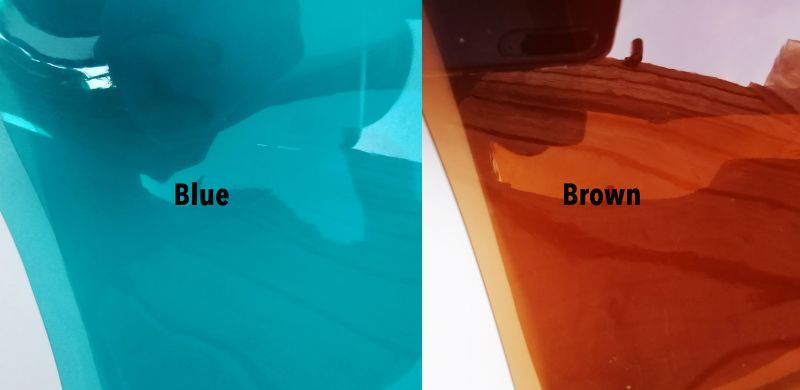

PVC

PVC

Okamoto's PVC film boasts world-class technology and quality, and is used for partitioning indoors and outdoors in factories and construction sites. It has excellent transparency and color development. 1mm thick.

PU punched leather

This artificial leather material was developed to address the shortcomings of conventional artificial leather, and is highly resistant to cracks, scratches, and rain. It is also used for school bags. The punching process makes it breathable and lightweight.

Rope (2 colors)

3 colors of thread

I'm looking forward to seeing what kind of work will be created.

About options.

Combining it with fur quilting, which can be easily removed with shoelaces, adds a touch of luxury.

This can be added for 4,500 yen + tax.

You can freely choose your favorite materials and create your own original quilted tassels.

The two-tiered tassel is available for 3,000 yen plus tax, and the three-tiered tassel is available for 4,000 yen plus tax. The tassels are removable with the shoelaces, so you can attach them to shoes other than Loper.

What is Loper?

With the goal of "creating a world where anyone can make shoes," the project took six years to plan and one year to develop the kit, and was announced at the end of 2018.

NO GLUE, YES ROPE

The shoe manufacturing process is very complex.

There are many complex and time-consuming manufacturing steps that involve the use of toxic adhesives. Even with good ventilation, it is nearly impossible to avoid inhaling toxic fumes while making shoes.

Project Roper was started from a desire to design a manufacturing system that is safer for the people and the environment involved in shoe manufacturing.

Production on Demand

I want to make only what is needed for those who need it.

A concrete measure to create a more sustainable and flexible production system is based on simplified production lines.

Roper shoes can be assembled by one person in a short amount of time without requiring any special equipment.

By minimizing capital investment costs and labor costs, we can create a system that delivers only what is needed to those who need it.

Easy assembly, easy setup

Mass-produced shoes are made in the world's cheapest factories and shipped all over the world.

This fact results in unnecessary environmental and economic costs.

The simplicity of the Roper system allows us to use materials from regions around the world and build flexible trade models that incorporate regional characteristics.

As a result, we aim to reduce carbon emissions and support the local economy.

share